Product Description

Model NO.: Elite Material: 100% Polypropylene Fiber Type: Monofilament Color: White Function: Reinforcement Product Name: Microfiber Raw Material: Polypropylene Tensile Strength: 450MPa Min Density(g/cm3): 0.91+/-0.01 Certificate 1: CE Trademark: elite-indus Origin: Anhui Usage: Concrete Feature: Reinforcement Pattern: Monofilament Width: as Per Order Structure: Micro Fiber Length: Times of 4mm/6mm with 1mm More or Less Fiber Diameter: 20um-30um Crack Elongation: 20+/-5% Acid &Alkali Resistance: Strong Certificate 2: ISO Specification: CE HS Code: 5503400000 Microfiber Monofilament Polypropylene PP

Fiber for Concrete reinforcement

PP Microfiber PROPERTIES:

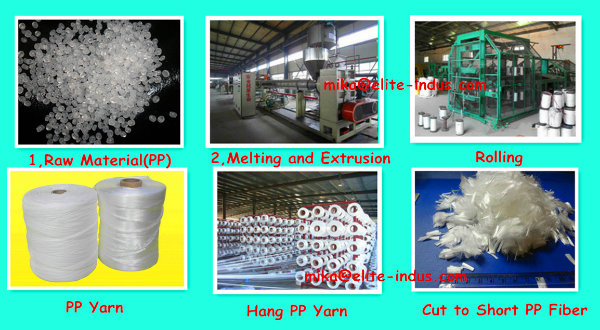

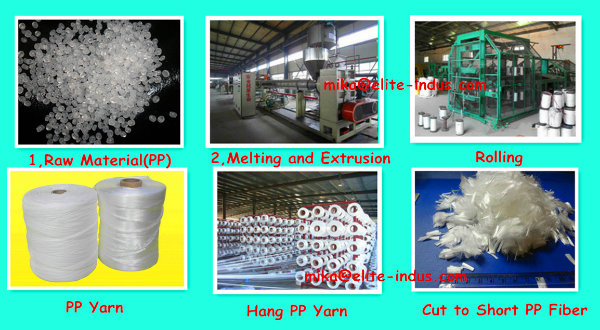

Our PP microfiber monofilament was produced by referring foreign advanced technology for

Fibers pinning, modified by adding functional additive and special surface-treating. Mixing into cement concrete, it has many advantages such as good dispersing, better water affinity, strong linking force. It is suited to reinforce and crack-resist to every kinds of cement concrete and mortar, specially used in engineering of building surface, floor, wall etc...

PP Microfiber APPLICATIONS:

1. Functions:

Resist to shrink & crack Increase seepage resistance

Increase friction resistance Increase freezing & thawing resistance

Improve tendons protection Replace steel net (using in plastering)

Prevent mortar split and crackle expansion

Increase impact resistance and peeling resistance

2,PP Microfiber Features:

A). No agglomeration and easily spread around in mortar or concrete. Guarantee the property of crack resistance effectively

B). Apply conveniently. No need to change the proportion of mortar, and just put the fibers into the mortar mixture and stir for a moment after adding water.

C). Has fine economic property. The equivalent dia. Of polypropylene monofilament is only φ0.02mm, so the ratio of dia. And surface is high and on the basis of crack resistance, it can reduce the amount (0.6kg/m 3 ) and cut down the cost effectively.

D). Be better to plaster. Because a great number of thin fibers spread into mortar evenly, so the plastering is much easier and this can improve the binding strength between surface and base.

E). The fiber has stable chemical property, strong acid &alkali resistance, and can be used in any engineering projects.

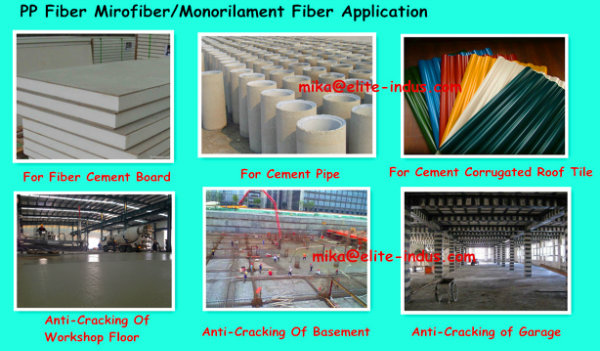

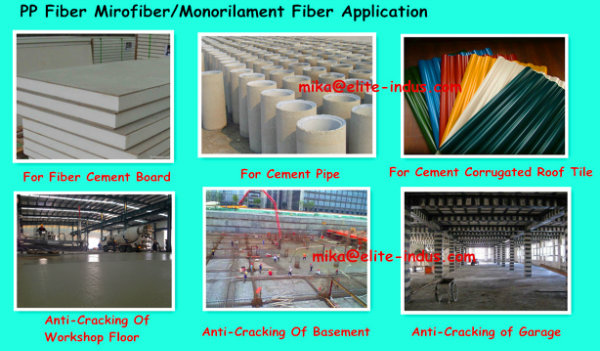

3. PP Microfiber Applications:

A). Suit for the waterproof layer, floor, inner & outer wall of industrial and civil construction.

B). Increase cracking resistance on the surface of industrial workshop, warehouse and parking lot.

C). Increase cracking & seepage resistance of the ground in natatorium, swimming pool, pond and ditch.

D). Suit for any mortar projects and common concrete projects.

E). Highway, bridge and other roads.

4. PP Microfiber Instruction:

A). Dosage: For resist the common cracks on surfaces, 0.9kg/m3 fibers to cement mortar Is enough, and for increasing reinforce and seepage resist application 1.8kg/m3 is enough.

B). Stirring requirement: The proportion of cement, sand and aggregate is no need to be changed. Put cement, aggregate, additive and fiber together, then stir after adding enough water and time for stirring can be prolonged for 2~3 minutes in order to make the compound mix completely. Also it can be mixed with cement and other aggregates in advance, stirring by adding water at worksite before construction.

PP Microfiber brief specification:

Raw Material : | Polypropylene | Crack Elongation: | 20+/-5% |

| Fiber Type : | monofilament | Fiber Diameter: | 20um-30um |

| Melting Point(C Deg.) : | 160 - 170 | Density(g/cm3) : | 0.91+/-0.01 |

| Acid &Alkali Resistance : | Strong | Tensile Strength(MPa): | 450 min. |

| Length: | 4,6,8,12,16,18,20,24,28,30mm times of 4mm or 6mm with 1mm more or less | water absorbency : | NO

|

PP Microfiber PACKING:

Normal packing is 0.6kg or 0.9kg or 1.0 kg/PE film bag, 18kg or 20kg/plastic woven bag,

9ton/20'gp, 20ton/40'HQ

Contact us if you need more details on

PP Fiber. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Polypropylene Fiber、Microfiber. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Concrete Additives > PP Fiber

Contact us if you need more details on PP Fiber. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Polypropylene Fiber、Microfiber. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on PP Fiber. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Polypropylene Fiber、Microfiber. If these products fail to match your need, please contact us and we would like to provide relevant information.