Product Description

Model NO.: Elt-bcf Function: Reinforcement Certification: SGS, ISO Width(M): 1m-6m Application: Landfill, Dam Ect. Mesh Center Distance(mm): 25.4/12.7mm Specification: CE HS Code: 39269090 Type:

Geosynthetics Material: Glassfiber Breaking Elongation(%): 4 Product Name: Bitumen Coated

Fiberglass Geogrids Feature: High Tensile Strength Trademark: elite-indus Origin: Anhui Bitumen Coated Fiberglass Geogrids

1, Fiberglass Geogrids Introduction

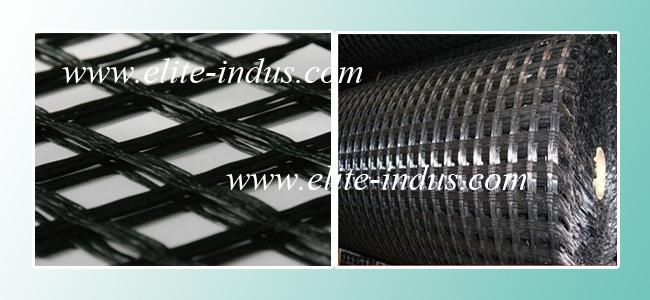

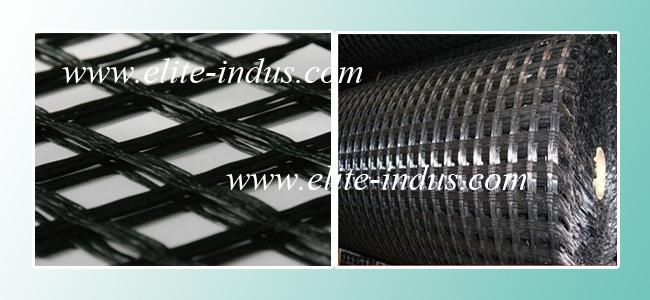

Fiberglass geogrid fiberglass rovings as the main raw material, Using the network structure of certain woven material made of, To protect the glass fiber and improve overall performance, through a special coating treatment process and the formation of new fine

Geotextile substrate.

2, Fiberglass Geogrids Feature

(1) High tensile strength, low elongation - Fiberglass geogrid is a glass fiber as raw material, has a high resistance to deformation, elongation at break of less than 3%.

(2) No long-term creep - as a reinforcing material, possess the ability to resist deformation in the case of long-term creep resistance load that is extremely important, glass

Fibers do not creep occurs, which ensures that the product can maintain long-term performance.

(3) Thermal stability - glass fibers above the melting temperature 1000 oC, which ensures that the geogrid fiberglass to withstand thermal stability in paving operations.

(4) Compatibility mixed with asphalt - fiberglass geogrid in the treatment process for the coating material is asphalt mixture design, Each fiber has been fully coated with asphalt with high compatibility, thus ensuring the fiberglass geogrid with asphalt mixture will not produce isolated asphalt layer, but firmly together.

(5) The physical and chemical stability - through a special coating treatment after treatment agent, fiberglass geogrid can resist all kinds of physical abrasion and chemical attack, but also against biological erosion and climate change, to ensure that their performance is not affected.

(6) aggregate interlocking and restrictions - is due fiberglass geogrid mesh structure, asphalt concrete aggregate can be running through them, thus forming a mechanical interlocking.

This limitation hinders the movement of aggregates, asphalt mix in the case load can be achieved by better compaction state, higher load-bearing capacity, better load transfer performance and less distortion.

3, Fiberglass Geogrids the role of the project

(1) strength, creep, to adapt to all kinds of environmental soil, fully meet the highway tall retaining wall use.

(2) can effectively improve the interlocking reinforced bearing surface, occlusal function, greatly enhanced level of foundation bearing capacity and effective constraint lateral displacement of soil, and enhance the performance of a solid foundation.

(3) Compared with the traditional grid more strength, strong bearing capacity, corrosion resistance, aging, friction coefficient, hole uniform, easy construction, long service life.

(4) more adapted to deep-sea fishing, embankment reinforcement, from the fundamental solution to the low intensity of other materials gabion of long-term water erosion caused by poor corrosion resistance, short life and other technical problems.

(5) can effectively avoid the construction process is rolling equipment, damage caused Construction injury

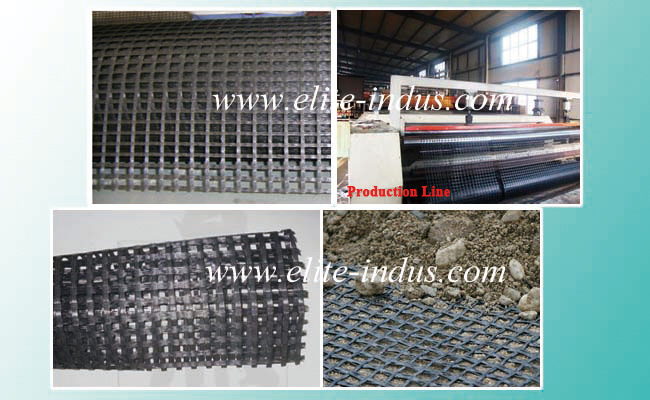

4, Fiberglass Geogrids Application

(1)applies to all kinds of roads, railways, airports enhance road embankment reinforced.

(2)the foundation for large parking garages and other permanent load and terminal enhancements.

(3)slope protection for railways, highways.

(4)applies culvert enhancement.

(5)applies to one-way stretch geogrid reinforced soil slopes after secondary (6)enhanced further enhance the soil, prevent soil erosion. Mining, tunnel reinforcement.

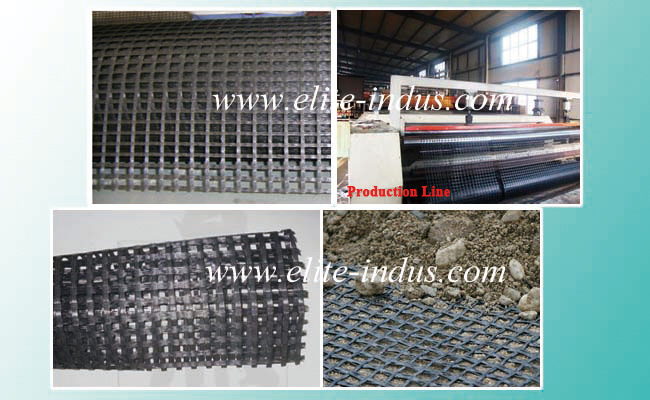

| Fiberglass geogrid technological standard(GB/T 21825-2008) | |

| specification | FGGa

30×30 | FGGa

50×50 | FGGa

60×60 | FGGa

80×80 | FGGa

100×100 | FGGa

120×120 | FGGa

150×150 | FGGb

50×50 | FGGb

80×80 | FGGb

100×100 |

| Mesh center distance(mm) | Longitudinal | 25.4±3.8 | 12.7±3.8 |

| Crosswise | 25.4±3.8 | 12.7±3.8 |

| breaking strength(kn/m) | Longitudinal | 30 | 50 | 60 | 80 | 100 | 120 | 150 | 50 | 80 | 100 |

| Crosswise | 30 | 50 | 60 | 80 | 100 | 120 | 150 | 50 | 80 | 100 |

| Breaking Elongation(%) | Longitudinal | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Crosswise | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Width(m) | 1m-6m | 1m-6m | 1m-6m | 1m-6m | 1m-6m | 1m-6m | 1m-6m | 1m-6m | 1m-6m | 1m-6m |

Contact us if you need more details on Fiberglass Geogrid. We are ready to answer your questions on packaging, logistics, certification or any other aspects about

Biaxial Geogrid、Fiberglass Biaxial Geogrid. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Geosynthetics > Geogrid & Geocell